As economies start to reemerge from COVID crisis mode, environmental, social, and corporate governance (ESG) factors are rising in importance. A global survey conducted by NAVEX Global shows that 67 percent of respondents in the US said their companies would increase focus on ESG factors in 2021.

The current US administration has given significant attention to the ESG-related issues so far. In light of this, the SEC is likely to renew its focus on climate change, its conflict minerals rule, and responsible sourcing in the coming months. Along with the recent implementation of the EU Conflict Minerals Regulation, the signs are that businesses should stay tuned for further developments.

What Are Conflict Minerals and Why Regulate Them?

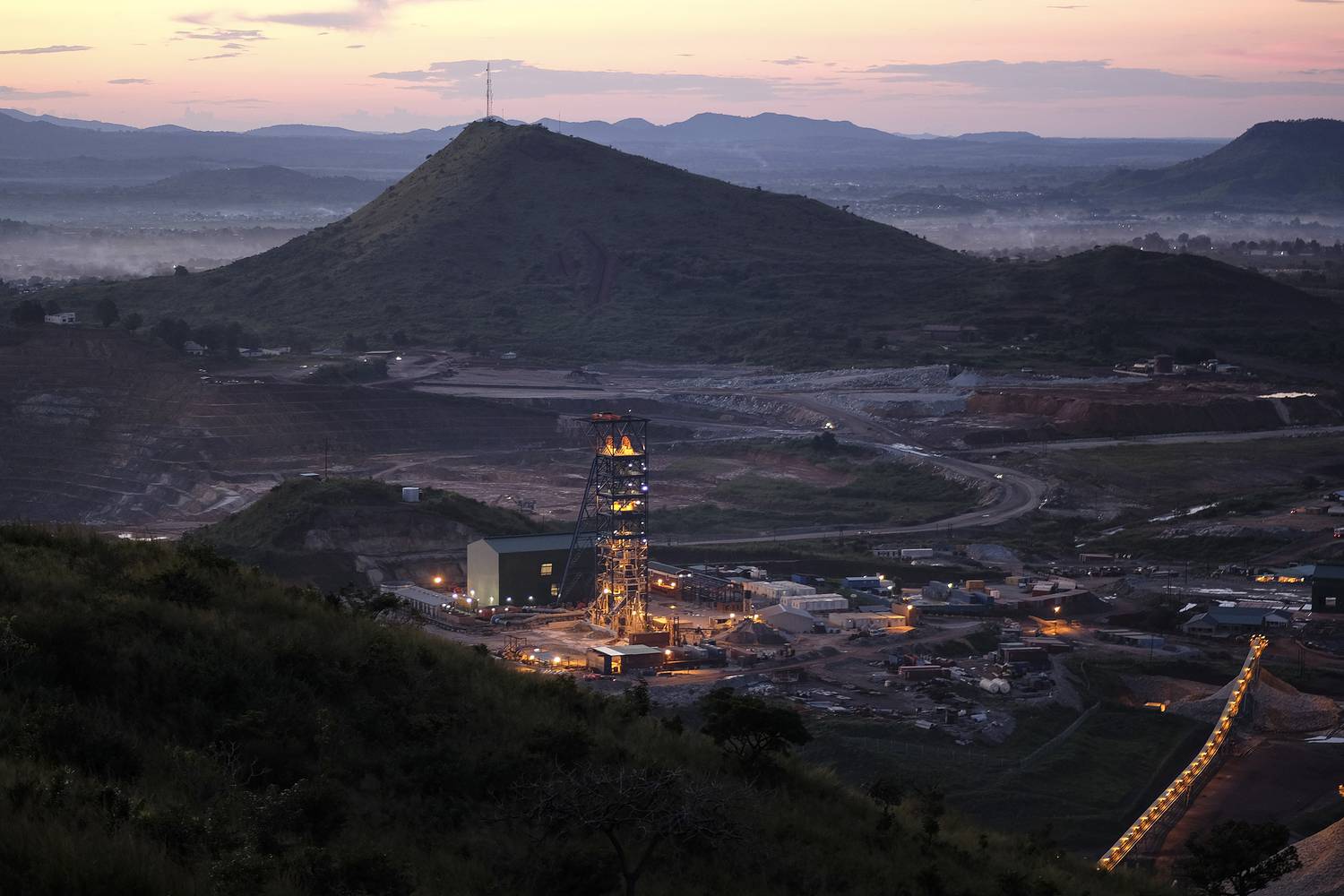

The term “conflict minerals” commonly refers to four elements: tin, tantalum, tungsten and gold (the “3TGs”) and their derivatives. These minerals are often mined in conflict zones, i.e. in conditions of armed conflict or fragile post-conflict with weak or non-existent governance, violations of international law, and widespread human rights abuses. The minerals trade can then be used to finance or benefit armed groups and fuel corruption, money laundering, violence, and forced labor. De-funding the armed groups is the primary objective of conflict minerals regulations.

Because of the wide use in electronics, automotive, medical devices, tooling, and aerospace industries, conflict minerals often end up in everyday consumer products such as cars, jewelry, or mobile phones. Multinationals can knowingly or sometimes unknowingly be affected by having them in their supply chains.

As of today, all existing regulations focus on these four elements. However, due to increasing demand for other minerals like cobalt and lithium, both essential for electric batteries, this scope is likely to expand in the future.

Existing Conflict Minerals Regulations and Initiatives

The growing concern over the use of conflict minerals in manufactured products led to legislative response, with the US being the earliest adopter. Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act of 2010 requires companies to undertake relevant due diligence and publicly disclose the use of conflict-implicated 3TGs if they are sourced from the Democratic Republic of Congo (DRC) or an adjoining country or if they are from recycled or scrap sources.

Pursuant to Section 1502, the SEC issued its conflict minerals rule in 2012. The Rule applies to a company using conflict minerals if:

- The company files reports with the SEC under the Securities Exchange Act, and

- The minerals are “necessary to the functionality or production” of a product manufactured or contracted to be manufactured by the company

Companies falling into this scope are required to take the following steps:

Step 1 Determine applicability of the regulation

Step 2 Conduct country of origin inquiry

Where conflict minerals originate in a covered country:

Step 3 Establish a due diligence process

Step 4 Obtain an independent private sector audit (IPSA) of the company’s due diligence efforts

Step 5 File a report

The Dodd-Frank Act does not prescribe a due diligence process, but it refers to the OECD Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas as a suitable framework. The EU Conflict Minerals Regulation (entered into force on January 1, 2021) also builds on this internationally recognized due diligence standard.

Although this is a crucial similarity between the two regulations, it is important to highlight that the EU Regulation is quite different from the Dodd-Frank, with the following key points of difference:

- The EU Regulation directly applies to importers of 3TGs, leaving manufacturers, importers, and sellers of finished products and components that contain 3TGs out of scope

- The EU Regulation exempts small volume importers of 3TGs introducing certain annual volume thresholds

- The EU Regulation is geographically non-specific and applies to 3TGs sourced from conflict-affected and high-risk areas (CAHRAs) that might exist all over the world

Along with the regulatory requirements, several industry initiatives are working to provide better traceability and responsibility along the mineral supply chains. US-based Responsible Minerals Initiative (RMI), founded by the members of the Responsible Business Alliance, is one of the most utilized resources helping companies make informed choices about responsibly sourced minerals. RMI provides tools and practical guidance documents for the industry, including the Responsible Minerals Assurance Process, global smelter/refiner lists and Conflict Minerals Reporting Templates (CMRT). Most companies across all industries and countries now use CMRT to engage with suppliers and gather conflict minerals supply chain information.

What Are Businesses Doing To Comply?

In response to regulations, government-backed voluntary initiatives, and consumer activism, corporate practices have changed. Many large companies have taken significant steps to account for potential ESG-factor driven risks in their supply chains.

Based on materiality assessments (using the SASB Materiality Map, for example), companies whose products incorporate 3TGs prioritized their action and reporting on due diligence practices with respect to human rights, indigenous rights, and operation in areas of conflict.

The way these companies have responded provides insight into how to manage and report on conflict minerals use to meet current and future market expectations.

Build Supply Chain Transparency

The first step is to gather detailed Reasonable Country of Origin Inquiry (RCOI) data for all metal vendors and suppliers. This is likely to present some practical complexity – mapping information for hundreds or even thousands of suppliers is a time-consuming process. Where conflict minerals originate in a covered country, you will need to survey suppliers on due diligence information and determine smelters in use, comparing them with those on the RMI-approved lists. Another RMI resource, the Responsible Minerals Assurance Process (RMAP), is a point of reference for arranging smelter/refiner audits necessary to validate their conformance with RMAP auditing standards.

Prepare and File an Annual Disclosure on Conflict Minerals

Companies are required to report on their “reasonable country of origin inquiry” and due diligence measures by filing a Specialized Disclosure report (Form SD) with the SEC. Form SD is due annually on May 31 on the prior calendar year. Depending on how many metal vendors and products you have, this may result in a lot of data. If this is your case, an automated conflict minerals management solution is advisable.

NAVEX ESG: Generate SEC Filings and Automate Due Diligence Inquiries

Think Strategically

Businesses are increasingly expected to understand and manage their exposure to ESG risks, including in the mineral supply chains. As public awareness of supply chain issues continues to grow, focusing on legal compliance alone is no longer sufficient to meet stakeholder expectations. A “beyond compliance” responsible conflict minerals sourcing program helps avoid public scrutiny, reduce the supply chain risks and enhance relationships with customers and suppliers. “Prioritizing ESG is an investment in competitiveness and future success,” – says Bob Colin, NAVEX Global CEO.

Conflict minerals sourcing falls outside of a company’s core operations, making it more difficult to identify the underlying risks typically driven by ESG factors, including human rights abuses, corruption, and environmental degradation. Left unmanaged, they can harm organizations’ reputations, operations, and financial performance.

The business case for effective management of ESG risk is therefore clear. Integrating ESG factors, along with a good ethical judgement, into the core of the business is now seen as essential to future company success. Now would be as good a time as any for all organizations to conduct a reality check on their progress and translate sustainability commitments into action.